Ceramic Glass Print

Printing with ceramic inks significantly differs from conventional inks. The main benefit of the ceramic ink lies in the strenght of the final product. The additional thermal processing (usually temepring) that the glass and ink undergo after the print binds them together and the end result is one solid product that is highly durable and resistant to scratching.

Technical specification:

| Minimal thickness | 4 mm |

| Maximum thickness | 19 mm |

| Minimal dimensions | 200 x 300 mm |

| Maximum dimensions | 3800 x 1600 mm |

GENERAL INFORMATION, VISUAL QUALITY AND ALLOWED TOLERANCES, INSTALLATION AND STORAGE GUIDELINES.

Pros and cons of ceramic print vs. conventional UV treated print:

| Ceramic glass pirnt | Conventional glass print | |

| Mechanical rigidity | Extremely rigid. | Can be damaged upon contact with a hard object. The painted layer needs to be protected or contact must be avoided. High risk during cleaning if not protected. |

| UV resistance | UV resistant, does not change color over time. | Becomes paler over time when exposed to UV for a long time (usually when used for exterior). |

| Color options | Minimal restrictions with red and magenta. | No limitation. |

| Price | Higher price due to the fact that the glass needs to be tempred after printing and the cost of the printing equipment. |

Application:

- Wall covers and kitchen backs.

- Glass doors and separating walls.

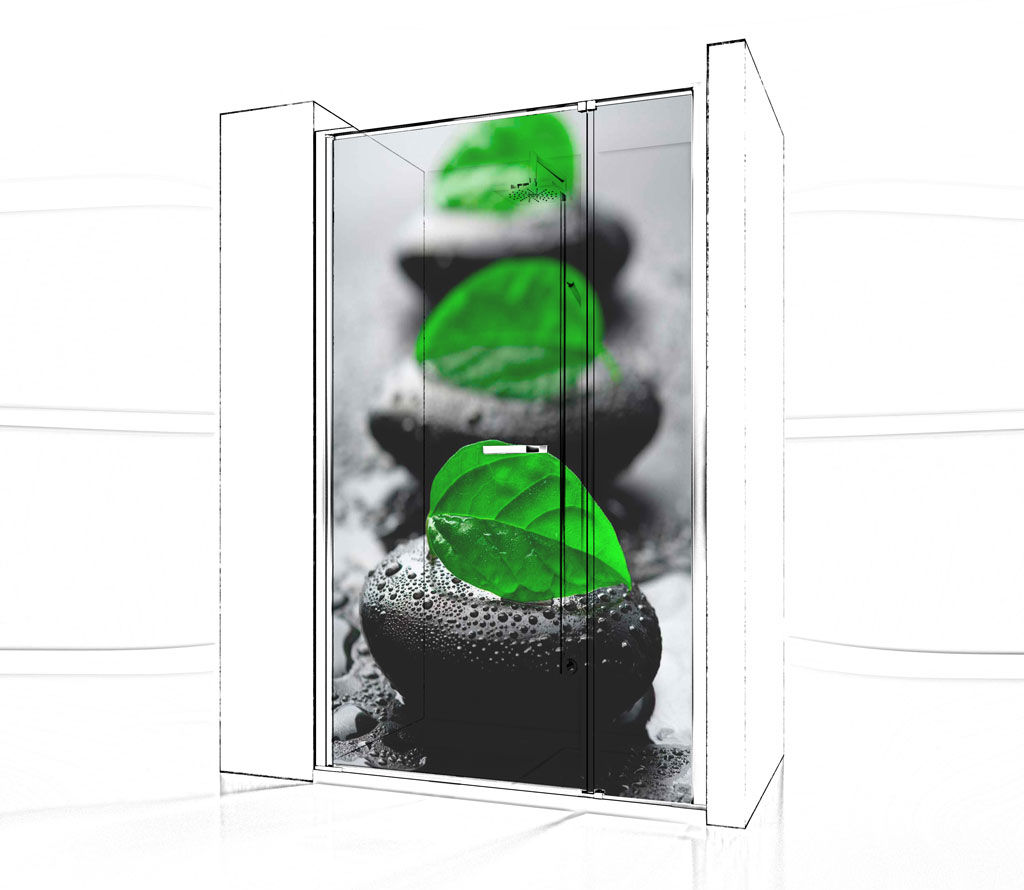

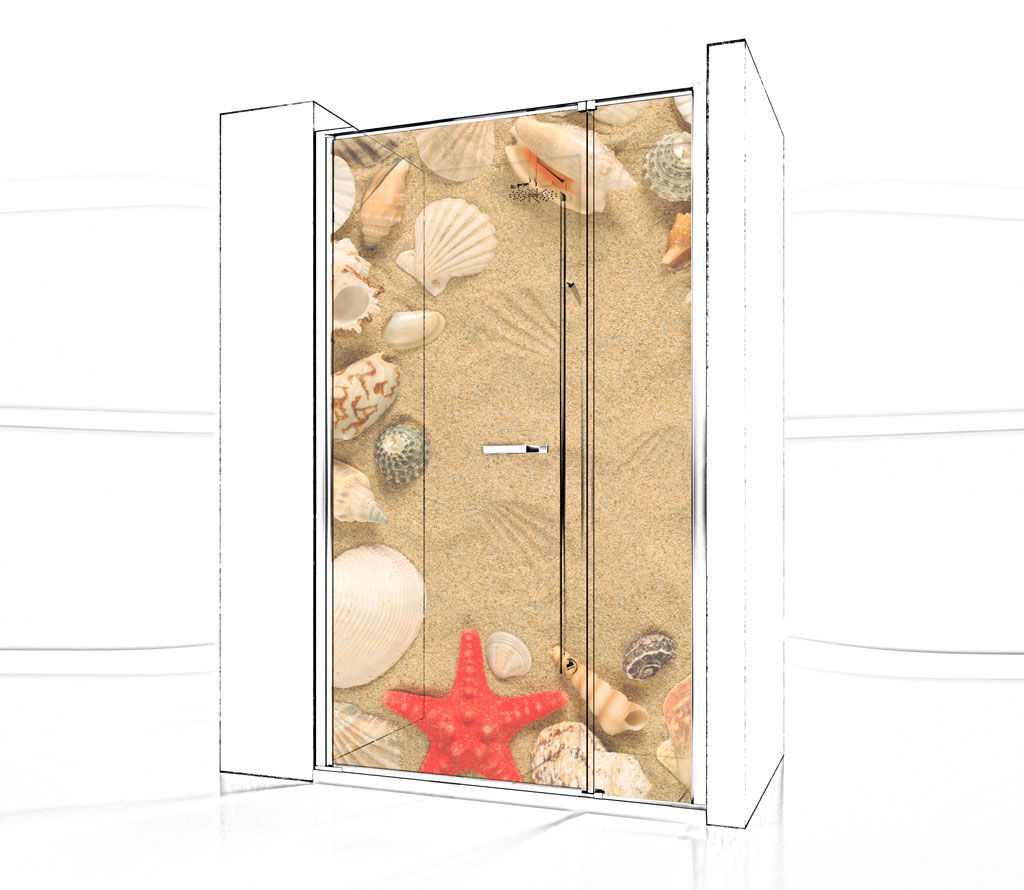

- Shower cabins.

- Decorative facade glazing.

- For spandrels and glass railings to hide concrete plates.

Bathroom and kitchen samples:

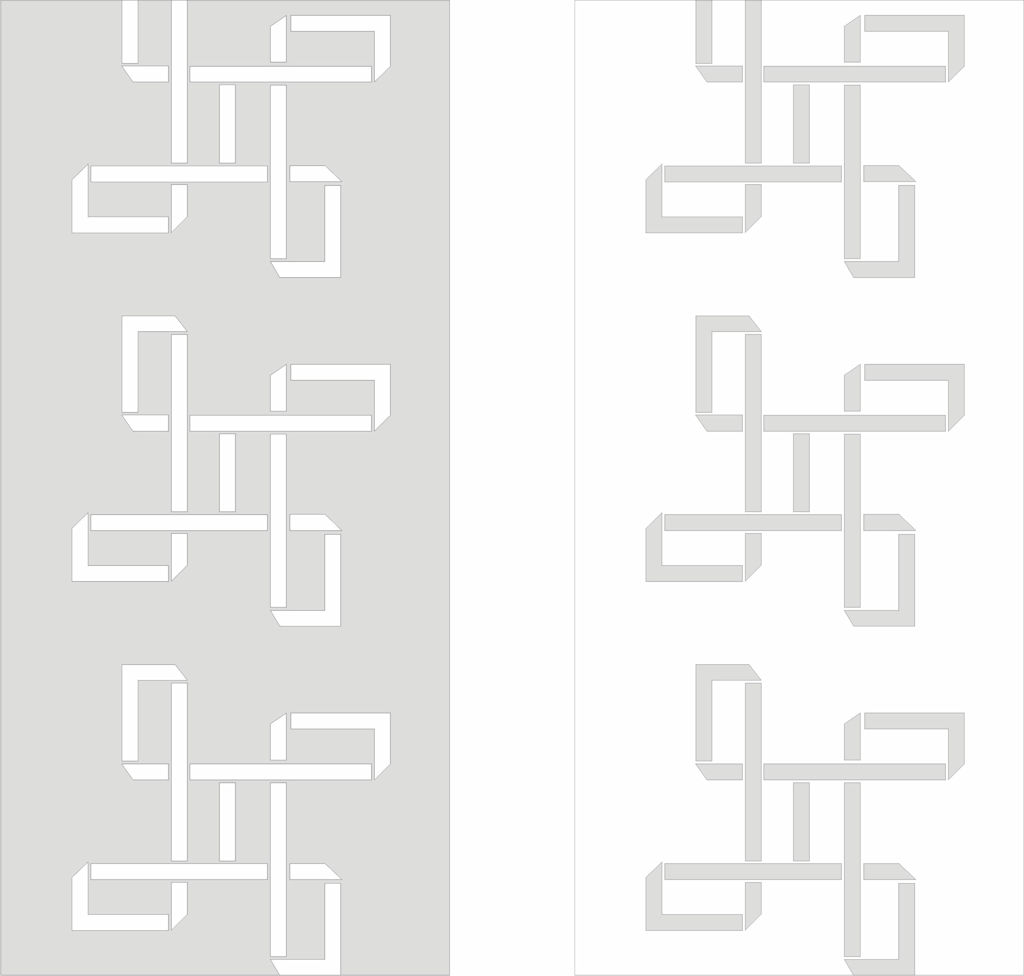

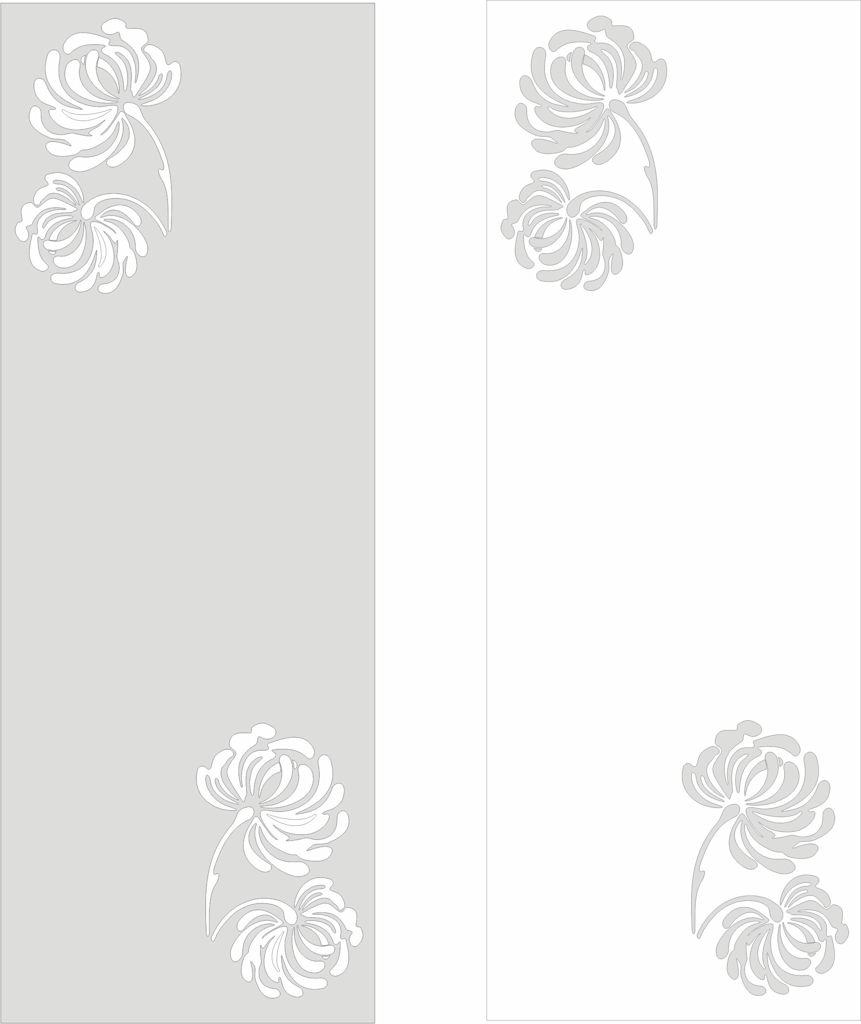

Sandblasted effect samples: